|

Main Page

|

|

|

New Technology

High

- Tech Harvest High

- Tech Harvest

The days of farmers sitting around

the country store swapping yarns and seat-of-the-pants

predictions for the growing season are long gone. Oh, the

farmers still talk and spin yarns, but mostly through e-mail

and Internet chat sessions. And the conversation today focuses

less on creaky-bone predictions of rain and more on precision

farming, the Global Positioning System (GPS), the reliability

of precise soil samplers, yield monitors and computer

interfacing problems

Local Irrigation

Water

may be readily available in the soil but not accessible to the

plant. Time-release water polymer gels that soak up water and

hold it for plant use have evolved into versatile, proven

water management tools. Superabsorbent gels on the market

today absorb from 30 to 800 times their weight in water. As

plants require water, their roots easily withdraw water from

the gel material. More than 90 percent of the moisture held in

the gel is available to the plant. After the growing season,

the products eventually degrade in the soil and disappear.

Some gels remain effective through many swell-shrink cycles

and can work for five years or more. Water

may be readily available in the soil but not accessible to the

plant. Time-release water polymer gels that soak up water and

hold it for plant use have evolved into versatile, proven

water management tools. Superabsorbent gels on the market

today absorb from 30 to 800 times their weight in water. As

plants require water, their roots easily withdraw water from

the gel material. More than 90 percent of the moisture held in

the gel is available to the plant. After the growing season,

the products eventually degrade in the soil and disappear.

Some gels remain effective through many swell-shrink cycles

and can work for five years or more.

Soil

researchers at Texas A&M University and the USDA Agriculture

Research Service (ARS) are developing a computerized

irrigation system that measures and calculates how much water

to apply every half-hour. The automated time domain

reflectometry (TDR) system uses stainless steel probes placed

in the ground at varying depths, from a few inches down to

several feet. A computer-controlled TDR instrument sends an

electronic pulse through a buried cable to the probes. The

longer it takes for the pulse to travel through the probes,

the more soil water. The probes work in most irrigated

agricultural soils and one TDR system can handle up to 241

probes. Soil

researchers at Texas A&M University and the USDA Agriculture

Research Service (ARS) are developing a computerized

irrigation system that measures and calculates how much water

to apply every half-hour. The automated time domain

reflectometry (TDR) system uses stainless steel probes placed

in the ground at varying depths, from a few inches down to

several feet. A computer-controlled TDR instrument sends an

electronic pulse through a buried cable to the probes. The

longer it takes for the pulse to travel through the probes,

the more soil water. The probes work in most irrigated

agricultural soils and one TDR system can handle up to 241

probes.

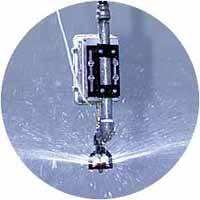

A new sprinkler head may help growers apply precisely the

right amounts of water and farm chemicals to their crops. The

head is designed to avoid over-irrigating, which wastes water

and can cause leaching of fertilizer or other chemicals into

underground water supplies. Unlike pulsating devices that

alternately turn the flow on and off, the variable-rate

sprinkler head never completely shuts off the flow. The amount

of flow that's blocked is determined primarily by the diameter

of a pin that moves in and out of the nozzle without altering

the area covered by the spray. The needle is controlled either

by an electrical power source or a hydraulic actuator

activated by a networked computer. In effect, each area within

the sprinkler's reach becomes a garden plot.

The sprinkler head can be incorporated into precision-farming

technologies. When an irrigation system delivers fertilizer or

other chemicals along with water - a technique known as

chemigation - application rates can again be customized to

take into account natural variables such as the fertility of

different soil types.

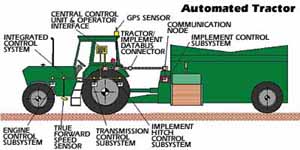

Today's

high-tech farmer needs to know as much about computers and

satellites as he does about agronomy and phases of the moon.

Modern precision farming allows farmers to work more

efficiently, while obtaining increased yields from their

crops. Theoretically, precision farming means using

information technologies such as GPS and geographic

information system software to gather, store, view and analyze

vast amounts of data - which can then be converted into usable

knowledge to make better farm management decisions for crop

production. Practically, precision farming means that farmers

can visualize, identify and control crop patterns from a

central computerized location. The goal is to improve

profitability and reduce risks. For example, an increasing

number of tractors are linked to GPS, so their position can be

tracked from a distant office. Land management information in

office computers then tells tractors where to go, stop, turn

or activate cutting or fertilizing equipment. Through a

tractor-based GPS, a farmhand is told when and where to turn

to begin tilling each row of a field. This can greatly reduce

overlap, which on a large farm saves hours of work. It all

works continuously in the field with a 3-in. accuracy, even

while the tractor is moving. Here is how the parts of today's

high-tech farm work and fit together. Today's

high-tech farmer needs to know as much about computers and

satellites as he does about agronomy and phases of the moon.

Modern precision farming allows farmers to work more

efficiently, while obtaining increased yields from their

crops. Theoretically, precision farming means using

information technologies such as GPS and geographic

information system software to gather, store, view and analyze

vast amounts of data - which can then be converted into usable

knowledge to make better farm management decisions for crop

production. Practically, precision farming means that farmers

can visualize, identify and control crop patterns from a

central computerized location. The goal is to improve

profitability and reduce risks. For example, an increasing

number of tractors are linked to GPS, so their position can be

tracked from a distant office. Land management information in

office computers then tells tractors where to go, stop, turn

or activate cutting or fertilizing equipment. Through a

tractor-based GPS, a farmhand is told when and where to turn

to begin tilling each row of a field. This can greatly reduce

overlap, which on a large farm saves hours of work. It all

works continuously in the field with a 3-in. accuracy, even

while the tractor is moving. Here is how the parts of today's

high-tech farm work and fit together.

Images from the robot

shepherd camera are analyzed by the computer program to find

the positions of the robot and flock. Electronic ear tags

allow individual pigs to be identified. A high-tech chicken

coop meters food and monitors health.

Yield Monitors

The

use of GPS in farming has grown beyond the early practice of

grid soil sampling and variable rate fertilizer applications

to a new, more useful focus on yield monitoring. In precision

farming, growers break fields down into regions, or cells,

analyzing growth characteristics of each cell and improving

crop health and yield by applying precise amounts of seed,

fertilizer and pesticides as needed. Many associate precision

farming with combine yield monitors, equipped with GPS. Some

farmers now use multi spectral imaging to produce gray scale

values that are converted to color images showing poor to good

vegetation conditions. The

use of GPS in farming has grown beyond the early practice of

grid soil sampling and variable rate fertilizer applications

to a new, more useful focus on yield monitoring. In precision

farming, growers break fields down into regions, or cells,

analyzing growth characteristics of each cell and improving

crop health and yield by applying precise amounts of seed,

fertilizer and pesticides as needed. Many associate precision

farming with combine yield monitors, equipped with GPS. Some

farmers now use multi spectral imaging to produce gray scale

values that are converted to color images showing poor to good

vegetation conditions.

Yield monitors can forecast yield as bushels per acre, total

pounds, acres per hour worked and grain moisture content. This

is all done while the combine is in use, and can be recorded

on a memory card for later analysis. Sensors monitor,

calculate and record, in real time, each field's yield as the

combine harvests the crop. This eliminates having to wait

until the entire harvest is complete before projecting yields

and making important decisions on how much to store or sell.

Field Scouting

Field scouting uses a portable geographic information system

unit that allows farmers to identify and record the location

of problems or events that will affect production - including

soil differences, insect infestations, fertility deficiencies

and weed problems. Remote sensing, and satellite and infrared

images also can be employed while scouting fields. Satellites

that capture infrared images can look at moisture content and

quickly assess the health of a crop before visible damage

appears. Soil testing, however, still requires farmers to walk

across their fields to take samples.

Smart Spraying

Equipment

is now available - and more is being developed - that will

allow chemicals to be applied to a single field at variable

rates. Sensors monitor tractor speed and adjust the amount of

fertilizer or pesticide sprayed on the soil. Equipment

is now available - and more is being developed - that will

allow chemicals to be applied to a single field at variable

rates. Sensors monitor tractor speed and adjust the amount of

fertilizer or pesticide sprayed on the soil.

Generally, the system records, in 2-second intervals, the

amount of pesticide that was applied.

A new "seeing-eye" sprayer for weeds uses a light-reflectance

sensor to scan the ground for patterns that match weeds. It

then kills them with less herbicide than conventional sprayers

use. The eight-row hooded sprayer uses its sensor to

distinguish differences in the light reflected from bare soil

and from weeds between crop rows. If it "sees" a weed, it

sprays it. The sprayer was developed for row crops through a

cooperative research and development agreement with Patchen,

of Los Gatos, Calif., and ARS scientists in Mississippi.

The Silsoe Research Institute (SRI) in Britain is looking into

improving the accuracy with which solid manure is spread onto

land. This system, based on a side discharge impeller-type

tanker spreader, features an electrohydraulic-operated

discharge control door and a novel driveline torque transducer

capable of sensing discharge rates in real time. The

integrated control system communicates with the tractor and

spreader subsystems to control engine speed, gear selection

and spreader settings. Once a desired application rate has

been selected, the system automatically adjusts the spreader

and/or tractor settings.

Sensors also can monitor the speed of a tractor and adjust the

seed planter to keep spacing consistent. This ensures optimal

spacing, while letting farmhands concentrate on other matters,

such as making sure the seed planter does not clog.

Robot Farmhands

Automation is even working its

way into the barnyard. Research into flock behavior and

modeling led a research team at SRI to develop a robot

that could enter a field, gather a flock of ducks and

steer them safely to a predetermined destination.

The robot system includes a robot vehicle, computer and

camera. Commands are then sent by radio to the robot,

which guides the ducks to the goal. Using ducks, instead

of sheep, allowed the trials to take place on a smaller

and more convenient scale. Duck flocking behavior is

recognized by shepherds as similar to sheep, and ducks are

often used in sheep dog training.

The project also looked at flock dynamics and how

individual animals in a flock behave.

Weighing pigs is the most basic guide to quality control

but it's time consuming and stressful to both farmers and

pigs. SRI has developed the Growth Rate and Conformation

Evaluation System, which uses image analysis techniques to

watch pigs grow. The image analysis system uses a video

camera connected to a computer, mounted over a feeder. The

computer measures

body area, ham width and ham area, and determines each

pig's shape, weight and growth rate.

During the 20th century mechanical technology made it

possible to feed a rapidly growing American population

while keeping the price of food lower than any other place

on earth. In this century, making these machines smarter

will extend these benefits to the world

|

|

|

Using satellite data, GPS

allows farmers to precisely steer equipment and map the

land to be tilled. |

|

For more Information Click

Here

|

|

|