|

Post Harvest Handling of

Mangoes

By Muhammad Iqbal

|

|

|

Currently

working as Chief Operating Officer Pakistan Horticulture

Development & Export Board, He has served the Federal

Government in different positions starting from mid

management to senior management for 30 years. Prior to

current position, he was serving FAO. He has attended a

number of national and international workshops, seminars

and expert consultations and has authored over 70

technical/research publications. |

Post - Harvest Handling System

Mangoes can be successfully stored for up to three weeks if

the recommended harvest maturity, post harvest handling and

storage conditions are employed.

Harvest Maturity

All mangoes to be exported by air should be harvested in the

physiologically mature, hard, green condition. Harvest

maturity in most varieties is judged by the position of the

shoulders in relation to the position of the stem as

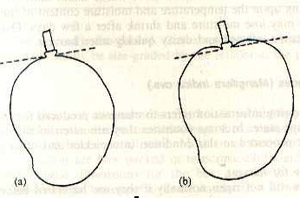

illustrated thru

Figure 1:

Figure

1: There is no sure way to know when mangoes are ready for

harvest. One of many methods is this: in immature fruit, the

shoulders are below the level of attachment of the stem (a);

in mature fruit, the shoulders have risen above the

stem-attachment level (b). This method does not apply to all

the cultivars and must be considered with other factors

Half mature fruits may be included in the shipment, but should

not make up more than 25% of the total. Fruit harvested in

ripe condition or with more than 15% yellow coloration, should

be selected in the field and not included in export shipments.

Ripe fruits are highly susceptible to bruising and mechanical

damage during handling and transport. Immature fruits should

not be shipped.

For mangoes exported by sea, the optimum stage of harvest

maturity is the half mature stage. Fruits should not show

any signs of softening or de-greening yellow colour

development. Immature fruits shout not be shipped.

Assessment of Harvest Maturity

in Mangoes

The following descriptions are appropriate for Sindhri &

Chaunsa and for other varieties which show similar

morphological characteristics.

Fully mature: outgrown shoulders, formation of a depression

with ridges at the stem end, firm and green;

Half-mature: shoulders in line with the slightly ridged

edges, firm and green;

Immature: shoulders below the stem insertion with ridges

absent, firm and green.

The maturity can also be determined by putting the fruit in 2%

salt solution. Those that sink are considered mature while

those that float are considered immature.

Harvesting

Where possible, mangoes should be harvested by hand from the

ground, by snapping the mangoes from the stem. Fully mature

fruit will detach easily, whereas half-mature fruit will not.

Optimum harvesting involves using secateurs and cutting the

stem 2 - 3 cm away from the fruit, and the latex allowed to

drain (this technique reduces latex exudation and staining and

reduces the possibility of entrance of fungal organisms).

Later the stem should be further trimmed with a sterilized

knife (dipping in a solution of calcium hypochlorite) to 0.5

or 0.3 cm as demanded by the importer. Where harvesting by

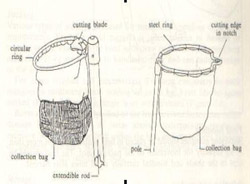

hand from the ground is not possible, harvesting implements

should be used. The most suitable involves a long pole with a

cutting blade and a small bag under the blade to catch the

fruit

(Figure 2).

(a) (b)

Figure 2:

Picking poles are used to harvest mangoes which cannot be

reached from the ground or ladder. Both the factory-made (a)

and home-made (b) types have cutting device and a catching bag Figure 2:

Picking poles are used to harvest mangoes which cannot be

reached from the ground or ladder. Both the factory-made (a)

and home-made (b) types have cutting device and a catching bag

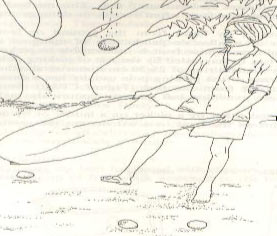

Alternatively, climbers may use cotton bags which are filled

and lowered to the floor. Mangoes should never be knocked from

the tree, dropped or thrown to the ground. Least option will

be that climber throws fruit which is held on sack and then

gently released to the floor

(Figure 3).

Figure 3:

Mango-picker in the tree drops the fruit, and catcher breaks

its fall using a jute sack supported by his hands and one

foot. He then lowers the bag to ground level and the mango

rolls out without damage

The out-grading should be carried out in the field to remove

immature, undersized, damaged, bruised, scald or ripe fruit.

The fruit on any one tree are of different ages because

flowering and pollination occurs over a period of several

weeks. Therefore, all the fruits do not mature simultaneously.

Fruits are usually harvested from individual trees on several

occasions throughout the season. damaged, bruised, scald or ripe fruit.

The fruit on any one tree are of different ages because

flowering and pollination occurs over a period of several

weeks. Therefore, all the fruits do not mature simultaneously.

Fruits are usually harvested from individual trees on several

occasions throughout the season.

After harvesting, latex should be allowed to drain away from

the fruit and the fruit placed in plastic field crates. Bags,

sacks and buckets are to be avoided as these generally result

in mechanical damage and bruising. Harvested mangoes should

not be left in direct sunlight, wind or rain, either in the

field or during transport from the field to the packing

facility.

Field

Heat Removal

The field heat of the fruit should be removed soon after

harvesting. It is essential for improved shelf life of

mangoes. Different methods can be applied for removing field

heat. These include air cooling, hydro-cooling, vacuum cooling

and forced air cooling. However, in our situation hydro

cooling is most appropriate and practical method. The fruit

should be immersed in ice cold water in field crates or in

bulk. The use of shower-type hydro cooler will be more

appropriate. Addition of sodium hyperchlorite (100 ppm) in

water will help in removing debris and latex stains.

Grading and Packing

On arrival in the packing area, the mangoes should be graded

for removal of immature, under-sized, damaged, blemished,

bruised, infested or ripe fruit. Fruits should be graded in

each carton according to the variety, size (giving a range of

counts for each shipment) and maturity (firm green full-mature

and half-mature fruits will ripen at different rates and

should not be packed in the same carton).

When packing, fruits should be placed leaning to the side

rather then directly on the base. Mangoes should be packed in

single layer one - or two - piece fully telescopic,

self-locking fiberboard cartons (bursting strength

requirements 250-275 lb/in2). Ventilation and handle holes are

recommended to provide adequate ventilation and ease of

handling. Cartons labeling requirements for the individual

markets should be followed. A layer of shredded paper in the

base of the carton is recommended, as this will assist in

cushioning the fruit. Each alternate mango in a carton should

be wrapped in a tissue to reduce fruit to fruit rubbing; small

identity labels attached to alternate fruit will assist in

product presentation. Net weight requirements are 2, 3, 4, 5 &

7 kg depending on the market destination. Cartons must not be

over-filled during packing.

Unitization

Palletisation is essential to minimize fruit damage due to

multiple handling. Movement of fruit within pack-houses or

during temporary storage can be aided by palletisation. For

sea-shipment exports of mangoes, palletisation is a necessity.

Pre-cooling

If mangoes are to be exported to the destination within two to

three days of harvesting, as with air-shipments, then

pre-cooling is advisable but not essential. Mangoes

transported by sea should be pre-cooled prior to loading into

containers or holds. Several methods of pre-cooling are

available, and the system adopted should suit the specific

requirements and capabilities. Temperature controlled rooms

are the most simple, although cooling may be slow if stacking

and spacing are not adequate to allow free and even air flow

or if the refrigeration capacity is low. A forced air system

is more efficient, although this requires a specially designed

unit and compatible packaging. Mangoes should be cooled to a

minimum of 120C.

Ripening and Storage

For export of mangoes by air, storage ripening may be required

prior to shipment. Recommendations for the optimum temperature

for ripening of mangoes vary according to the variety and

growing conditions although the range of 200 to 250C is

usually considered optimum. Temperatures above 250 to 300C may

result in ripe fruit with off-flavours and mottling of the

peel. Initiation and synchronization of ripening period of

mangoes can be achieved with exposure to ethylene gas, whether

direct from cylinders or as liberated from ethephon when

utilized with a catalytic generator. Acetylene gas liberated

from calcium carbide exhibits similar effect. Treatments with

gases are carried out in air-tight room from 24 hours at 200

to 250C, 90 to 95% relative humidity. Concentrations of gas

required during exposure are 10 -100 ppm (0.001 - 0.01%) for

ethylene and 1000 ppm (0.1%) for acetylene. Concentrations of

gases are controlled by adjusting flow deliveries or the

volume of ethylene delivery liquids (such as ethephon).

Air-tight rooms should have adequate air circulation to enable

uniform distribution of gas throughout the room. Build-up of

carbon dioxide is to be avoided as this reduces the effect of

the ethylene and will have a detrimental effect on fruit

ripening.

Prolonged storage of more than three to five days should not

be used for air-freighted fruit. Prolonged storage should be

used in the case of sea-freighted mangoes. At storage

temperatures below 120C unripe mangoes will develop chilling

injury, which will lead to a drastic reduction in fruit

quality and increased spoilage. Storage at 120C with 85-95%

relative humidity will maintain the fruit in an acceptable

condition, and which will ripen satisfactorily on transfer to

higher temperatures. These criteria depend on the variety,

harvest maturity and the time of harvest in the season. Fully

mature fruits have been found to show a reduced storability

when compared to half-mature fruits, and this factor becomes

more important as the season progresses. Strict levels of

quality control in low temperature stored fruit are essential,

as blemishes, bruises, damage and infections will manifest to

a greater degree than when exported by air and marketed

rapidly. The potential exists in stored fruit for high levels

of spoilage and poor quality. Prolonged storage of more than three to five days should not

be used for air-freighted fruit. Prolonged storage should be

used in the case of sea-freighted mangoes. At storage

temperatures below 120C unripe mangoes will develop chilling

injury, which will lead to a drastic reduction in fruit

quality and increased spoilage. Storage at 120C with 85-95%

relative humidity will maintain the fruit in an acceptable

condition, and which will ripen satisfactorily on transfer to

higher temperatures. These criteria depend on the variety,

harvest maturity and the time of harvest in the season. Fully

mature fruits have been found to show a reduced storability

when compared to half-mature fruits, and this factor becomes

more important as the season progresses. Strict levels of

quality control in low temperature stored fruit are essential,

as blemishes, bruises, damage and infections will manifest to

a greater degree than when exported by air and marketed

rapidly. The potential exists in stored fruit for high levels

of spoilage and poor quality.

Shipment Conditions

For air-shipmen, it is preferable, although not essential,

that transport occurs on aircraft pallets rather than in

containers. Shipment in aircraft containers may result in

build-up of heat and ethylene which will accentuate ripening.

For sea shipments, efficient reefer containers should be used

in preference to break bulk system in the hold. Stacking

system should allow for sufficient ventilation to assist in

temperature maintenance.

Potential Post Harvest Losses

Mechanical Damage

Mechanically damaged fruit will normally deteriorate rapidly

and should not be exported. Damaged regions are susceptible to

microbial infection, particularly when low temperature

long-term storage is used. Careful handling should therefore

be used during harvesting and handling operations such as

grading, packing and transportation.

Low Temperature

Storage at temperature below 120C will result in chilling

injury, the symptoms of which include inhibition of ripening,

pitting, internal discoloration, prey scald like discoloration

of the skin, increased water loss, increased susceptibility to

decay and detrimental changes in flavour.

Pathological Factors

Infection by micro-organisms is generally the most serious

cause of post-harvest losses in mango. Disease incidence can

be reduced by good orchard management, pre-harvest cultural

practices, appropriate handling and post-harvest treatment

procedures. Washing in static water tanks will increase

disease incidence due to the increase in inoculums from

infected fruit, therefore, water has to be changed frequently

and contain sodium hypochlorite (100 ppm) and/or suitable

fungicide. Post-harvest applications of specific fungicides

will assist in disease control.

The important diseases and pests

of mangoes include the following:

o Anthracnose (Colletotrtchum gloeosporfofdes) infection

occurs in the leaves, stem, young flowers and fruits. In the

first three, infection results in depressed black circular or

angular lesions; these enlarge and coalesce and affect large

areas. Infections of the fruit are usually latent and manifest

only as the fruit begins to ripen. Anthracnose is

characterized in ripening fruit by small black circular

lesions which gradually enlarge and coalesce as the fruit

continues ripening.

Mangoes harvested from areas or trees which are known to

suffer from anthracnose or for fruit destined for long term

storage, treatment is required in hot water bath (550C for 5

minutes) containing 0.05% Thiabendazole. This technique shows

good control of anthracnose, but generally requires the use of

specialized equipment, as temperature control of the water

bath is essential for the effectiveness and prevention of

fruits damage. After fungicide treatment, the fruit should be

allowed to cool and dry for preparation for grading and

packing.

o Stem end rot (Diplodfa natalensts) is particularly apparent

during low temperature storage. Infection is characterized by

light grey-brown areas in the stem region. Infection is

believed to occur through the cut stem. Disease incidence can

be reduced by leaving 1 cm of stem attached to the fruit.

o Rhizopus rot (Rhizopus oryzae) develops rapidly at 250C and

is characterized by skin splitting and development of course

white mould with black spore heads. Infection takes place

after harvest, usually through mechanical injury. The

incidence can be minimized by careful handling, hygienic

conditions and rapid cooling.

o Jelly Seed is usually found only when the fruit is sliced;

affected fruit show watery translucent tissue around the stone

towards the stem-end which then spreads. The condition is

found in harvested fruit but develops as the fruit ripens. The

only means of control at present is early harvesting, but this

may result in the export of immature fruits.

o Fruit Flies are among the serious quarantine pests and

therefore restrictions are imposed on mangoes imports by many

countries including China, Iran and Japan. Ideally there have

to be less pest prevalence areas combined with recommended

post-harvest treatments to satisfy the importers. The

integrated pest management technique of controlling fruit

flies is world wide accepted and preferred mode. Hence this

needs to be widely adopted. Regarding post-harvest treatments,

the fruit has to be treated by hot water dip, vapour heat

treatment or irradiation. The facilities for hot water dip are

limited while those of vapour heat treatment and irradiation

at experimental scale only. The development of these

facilities on commercial scale is needed.

Post Harvest Handling of Mangoes

Quality Criteria

Market requirements state that

mangoes on arrival should be:

Physiologically mature;

Commencing ripening with 30 to 50% coloration;

Significant area of golden colour on the fruit shoulders;

Relatively firm;

Minimum sugar content of 10%;

Uniform shapes;

Free from disease, decay, sunscald, cracks, bruises, latex

stains, insect and mechanical damage; and

Conform to the weight and size specifications.

Volume sales of mangoes are based on presence of the golden

colour, acceptable size of ripeness for consumption, uniform

size grading, uniform stage of ripeness and the absence of

disease or damage.

Pakistan Horticulture

Development & Export Board.

|

Pakissan.com;

|